At first glance, a solar panel looks like a single, solid unit. But it's actually a carefully engineered "sandwich" of different materials, with each layer playing a crucial role in turning sunlight into electricity for your home. The main parts of a solar panel include the hardworking células fotovoltaicas (FV), a tough glass shield, layers of protective sealant, an insulating backsheet, and a rugged aluminum frame holding it all together.

On the back, a small junction box is the central hub where all the generated electricity is collected.

Deconstructing the Modern Solar Panel

Think of a solar panel as a high-tech lasagna. Each layer is selected for a specific job, and they all have to work together perfectly to ensure the panel not only produces power efficiently but also survives for decades out in the harsh elements. The quality of basic materials, like the glass and frame, is just as important for a solar panel as understanding the importance of glass and aluminium in construction is for a building.

The technology inside these panels has come a long way, especially as global solar capacity exploded to over 512 gigawatts by the end of 2018.

%%{init: {"theme":"base"}}%%

line

title Global Solar PV Capacity Growth (2000–2018)

x-axis: 2000,2005,2010,2015,2018

y-axis: 0,100,200,300,400,500,600

"GW": 17,61,140,225,512

Yet, the core components have remained largely the same: silicon cells, protective glass, encapsulant, a backsheet, and an aluminum frame.

To get a better handle on how it all fits together, let's break down the main components and what they do.

Quick Guide to Solar Panel Components

This table gives you a quick snapshot of the primary parts of a solar panel and their main purpose.

| Componente | Función principal | Common Material |

|---|---|---|

| Células fotovoltaicas (FV) | Converts sunlight directly into DC electrical current. | Silicio (monocristalino o policristalino) |

| Tempered Glass | Protects the PV cells from weather and impact. | High-transparency, low-iron tempered glass |

| Marco de aluminio | Provides structural stiffness and durability. | Anodized or powder-coated aluminum |

| Encapsulant (EVA) | Bonds the layers together and protects cells from moisture. | Etilvinilacetato (EVA) |

| Lámina posterior | Acts as a moisture barrier and electrical insulator. | Polymers like PP, PET, or PVF |

| Caja de empalmes | Houses wiring and diodes; collects and transfers power. | Plastic enclosure with bypass diodes |

Each of these parts is a piece of a complex puzzle, designed to maximize energy output and ensure your solar investment lasts for years to come.

The Engine Room: Photovoltaic Cells

At the very heart of every solar panel, you'll find the células fotovoltaicas (FV). These are the true engines of your system, the components doing the heavy lifting. This is where the magic really happens—sunlight hits the cell and gets converted directly into electricity.

Think of them like the individual leaves on a high-tech tree. Each cell captures sunlight and, through a process called the photovoltaic effect, creates usable power for your home.

The quality and type of these cells are the single biggest factors in a panel's overall performance. When sunlight strikes the silicon in a PV cell, it knocks electrons loose, creating a flow of energy. This flow is the direct current (DC) electricity that powers your entire system.

Células monocristalinas frente a policristalinas

Almost all PV cells on the market today are made from silicon, but they come in two main flavors: monocrystalline and polycrystalline. While they both do the same basic job, how they're made and how they perform are quite different. Getting this choice right is a huge part of learning cómo elegir paneles solares that fit your needs.

The difference really comes down to purity. Monocrystalline cells are sliced from a single, pure silicon crystal. This gives them their classic uniform black look and, more importantly, a clear path for electrons to travel, which boosts efficiency.

Polycrystalline cells, on the other hand, are made by melting multiple silicon fragments together. This process creates that distinctive speckled blue, marbled appearance. It's more cost-effective, but the boundaries between the crystals slightly hinder electron flow, resulting in lower efficiency.

To make things a bit clearer, here's a quick breakdown of how these two cell types stack up against each other.

| Característica | Monocrystalline Cells | Polycrystalline Cells |

|---|---|---|

| Eficacia | Superior (15-24%) | Inferior (10-18%) |

| Coste | More Expensive | More Affordable |

| Apariencia | Uniform black, octagonal shape | Speckled blue, square shape |

| Lifespan | Typically Más de 25 años | Typically Más de 25 años |

%%{init: {"theme":"base"}}%%

bar

title Cell Efficiency Comparison

x-axis: Cell Type

y-axis: Efficiency (%)

Monocrystalline: 24

Polycrystalline: 18

So, what's the takeaway? The decision usually boils down to a trade-off between performance, space, and your budget. If you have limited roof space and want to maximize your power output, the higher efficiency of monocrystalline panels is often worth the extra cost. But if you have a larger area to work with, polycrystalline panels can offer a fantastic return on investment.

The Armor: Glass and Backsheet

What good is a high-performance engine if it's left exposed to the elements? The same logic applies to solar panels. The real workhorse components—the photovoltaic cells—need serious protection to survive decades out in the sun, wind, and rain.

That's where the glass and backsheet come in. Think of them as the panel's armor, shielding the delicate power-generating parts from everything mother nature can throw at them.

The very top layer is a sheet of high-transmission, low-iron tempered glass. This isn't your average window pane. It's specially engineered to be incredibly tough—strong enough to handle impacts from hail and heavy snow loads—while also being crystal clear to let as much sunlight as possible pass straight through to the cells.

A Protective Sandwich

This glass is actually part of a laminated "sandwich" that seals the solar cells in for good. A special adhesive layer, called an encapsulant, is used to bond the glass, cells, and backsheet together. It creates a single, unified block that's completely moisture-proof.

The final layer at the very bottom is the hoja posterior. This tough polymer sheet is the unsung hero of the panel, providing a few critical functions:

- Electrical Insulation: It keeps the electrical current safely contained within the panel.

- Barrera contra la humedad: It acts as a final, impermeable shield against humidity and rain that could seep in and cause corrosion over time.

- UV Protection: It stops ultraviolet radiation from degrading the internal components from behind.

This layered, sealed construction is precisely why solar panels are so incredibly durable. It's the secret behind manufacturer warranties that often guarantee performance for 25 años o más.

This tough-as-nails design ensures your panels can keep producing power reliably, year after year. Of course, keeping that top layer of glass clean is key to getting the most out of them. For tips on that, check out our guide on how to clean solar panels.

Ultimately, the combination of glass, encapsulant, and backsheet creates a rugged, weatherproof package that protects your energy investment for its entire lifespan.

The Sturdy Skeleton: Aluminum Frame

When you look at a solar panel, the first thing you probably notice is the sleek grid of cells under glass. But what holds that entire package together? That's the job of the marco de aluminio.

Think of the frame as the panel's skeleton. It’s the rigid, strong, yet surprisingly lightweight structure that provides the backbone for all the other components. Without it, the delicate layers would be far too fragile to handle.

Built to Withstand the Elements

The frame's primary job is protection. It shields the vulnerable edges of the glass from chips and cracks during transportation and, more importantly, once it's on your roof. It also provides the structural rigidity needed to prevent the panel from flexing or twisting under heavy wind or snow loads, which could easily create micro-cracks in the solar cells and kill your power output.

That's why the industry standard is aluminio anodizado. This isn't just plain metal; the anodization process creates an incredibly tough, corrosion-resistant layer. It means the frame won't rust or degrade, even after facing decades of sun, rain, and ice.

This focus on structural integrity is a key part of modern solar panel design. It ensures the panel not only produces power but can withstand environmental forces for its entire 25+ year lifespan.

The way solar panels are built has come a long way from the early days. Today's high-efficiency silicon panels are a sophisticated sandwich of materials, from the protective glass and encapsulant to the cells themselves and, of course, the sturdy frame holding it all together. You can learn more about this evolution in the history of solar power at Sun Valley Solar.

Finally, the frame is what makes installation possible. It's designed with channels and pre-drilled holes that allow installers to securely bolt the panel to a racking system. This ensures your panels stay put, year after year, turning sunlight into savings. It’s the final piece of the puzzle, locking everything into a single, reliable unit ready for the real world.

The Junction Box: Your Panel's Mission Control

If you flip a solar panel over, you'll find a small, unassuming plastic box. That's the caja de empalmes, and it's basically the panel's mission control. It's a tough, weatherproof enclosure where all the connections from the solar cells come together. From this central point, the power your panel generates is safely routed out through cables on its way to your inverter.

But the junction box does more than just channel electricity. It houses some of the most important, yet least-talked-about, parts of a solar panel: the diodos de bypass. These little electronic gatekeepers are the secret to keeping your system running smoothly, especially when conditions aren't perfect.

Keeping Power Flowing with Bypass Diodes

Imagine a single solar cell gets covered by a stray leaf or some bird droppings. That shaded cell suddenly stops producing power and, worse, acts like a roadblock, jamming up the flow of electricity from all the other healthy cells in its group. The whole section would just shut down.

This is where the bypass diodes save the day. They act like a smart detour on a highway. The moment a diode senses a high-resistance "traffic jam" from a shaded cell, it opens up an alternate path. This allows the current from the healthy cells to flow right around the obstruction, completely bypassing the underperforming cell.

By cleverly redirecting the flow of electricity, bypass diodes ensure that a small patch of shade on one part of the panel doesn't tank the performance of the entire module.

Thanks to these components, the rest of your panel can keep pumping out power, even as clouds, trees, or debris create shifting shadows throughout the day. They are a simple, automatic, and absolutely critical feature for maximizing your real-world energy harvest.

How All the Solar Panel Parts Work Together

Knowing the individual parts of a solar panel is a great start, but the real magic is in how they all work in perfect concert. It’s a beautiful dance of physics and engineering, turning sunlight into the electricity that keeps your lights on.

Let's follow the journey of a single photon of light to see how it all happens.

It all starts when that photon passes through the anti-reflective glass, which is designed to let as much light in as possible. The photon then hits a silicon solar cell, and bang—it knocks an electron loose. That simple action is the heart of the photovoltaic effect, and it’s the very beginning of an electrical current.

From a Loose Electron to Your Home's Power Grid

Once that electron is free, the solar cell’s built-in electrical field gives it a push, directing it to join a river of other electrons. This flow creates a direct current (DC). This current zips along the thin metal busbars on the cell's surface and makes its way to the panel’s command center: the junction box.

From the tough backsheet to the sturdy aluminum frame, every single component is there to protect this process and ensure that tiny electron's journey is a safe and productive one for decades.

Once all the DC electricity is collected in the junction box, it's sent out of the panel. The final, crucial step happens in a separate device called an inverter, which converts that DC power into the alternating current (AC) your home appliances actually use. To get the full picture, you can learn more about qué son los inversores solares and see how they finish the job.

Think of the flow like this:

- Step 1: Sunlight beams through the specialized glass layer.

- Step 2: A light particle hits a solar cell, freeing an electron.

- Step 3: These electrons flow together as DC current toward the junction box.

- Step 4: The current leaves the panel and heads straight for the inverter.

Common Questions About Solar Panel Parts

Now that we’ve broken down a solar panel piece by piece, let's tackle some of the practical questions that homeowners ask all the time. Getting a handle on these details gives you a much clearer picture of how durable your solar investment really is and what to expect down the road.

Which Solar Panel Part Fails Most Often?

Modern solar panels are built like tanks, but nothing is completely indestructible. Over a 25+ year lifespan, it’s rarely the solar cells that give out.

More often than not, the weak links are the protective layers—the encapsulant or the backsheet. After decades of exposure to sun, rain, and temperature swings, these materials can start to break down, potentially letting moisture creep in. The junction box and its internal bypass diodes are also common culprits, as they bear the brunt of environmental stress year after year.

Can I Replace Individual Parts of a Solar Panel?

For the most part, no. Think of a solar panel as a permanently sealed and laminated sandwich. This design is fantastic for durability, but it makes it impossible to swap out a single cracked cell, a broken piece of glass, or a torn backsheet.

The one exception is sometimes the junction box or its diodes. However, this is a delicate repair that absolutely requires a qualified technician. In almost every other case of significant damage, the entire panel has to be replaced.

This sealed, all-in-one design is precisely what makes panels so tough and weatherproof. While it limits repairs, it’s the key to protecting the sensitive electronics inside from dirt, moisture, and physical damage for decades.

How Does Each Part Affect Efficiency?

Every single component has a job to do when it comes to a panel's overall efficiency. The type of photovoltaic cell is the star player, of course, but the supporting cast is just as critical for preventing energy loss.

For example, that revestimiento antirreflectante on the glass isn't just for show; it ensures as much sunlight as possible actually reaches the cells. Likewise, high-quality wiring and well-functioning diodes in the junction box make sure the power you generate doesn't get wasted before it even leaves the panel.

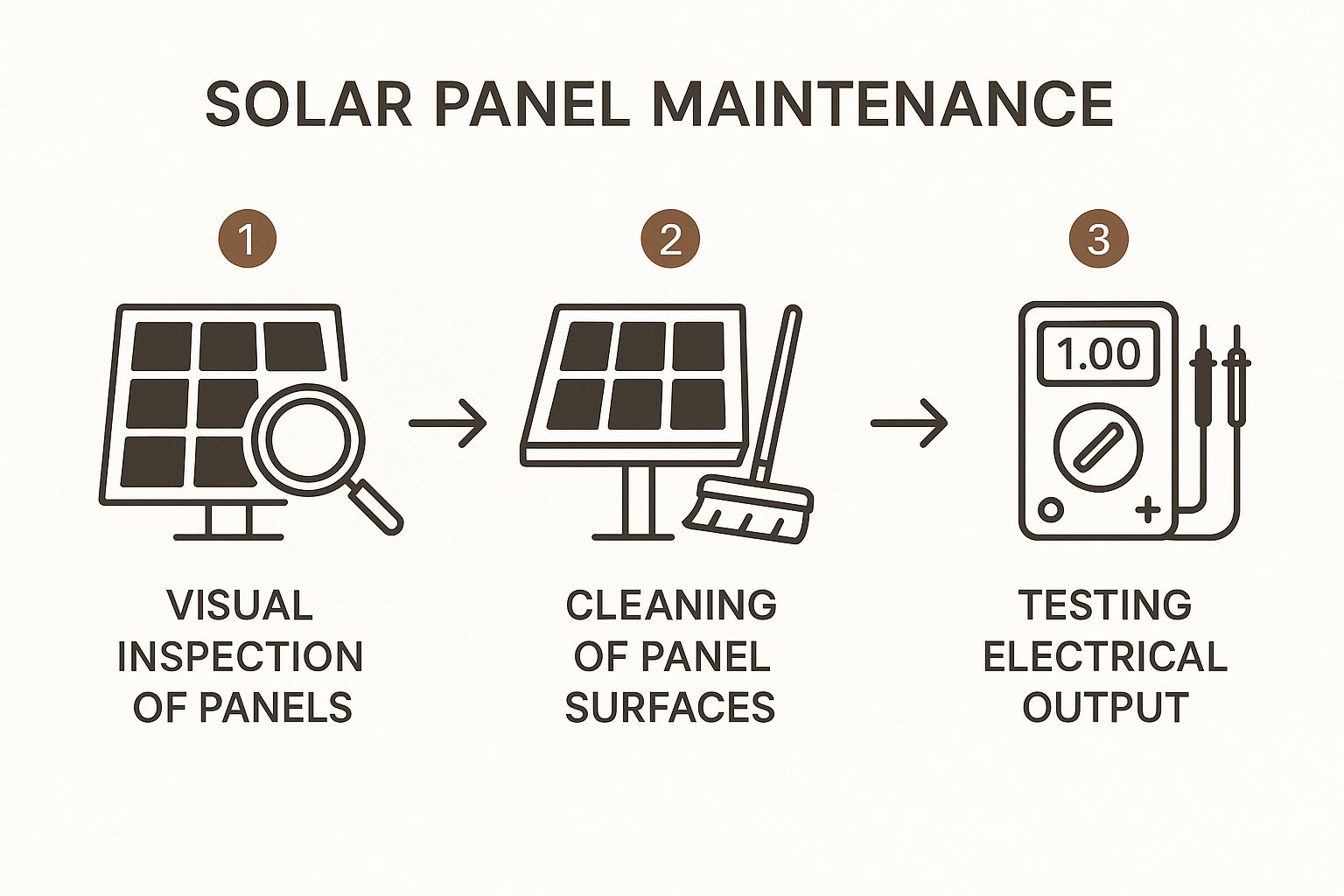

This simple maintenance flow shows how to keep all those parts working together at their best.

This process highlights how regular inspection, cleaning, and testing ensure every part contributes to peak system performance.

Ready to put the sun to work with a system built from high-quality, durable components? The experts at Energía radiante can design a solar solution perfectly suited for your home. Explore your options with us today!